Blog

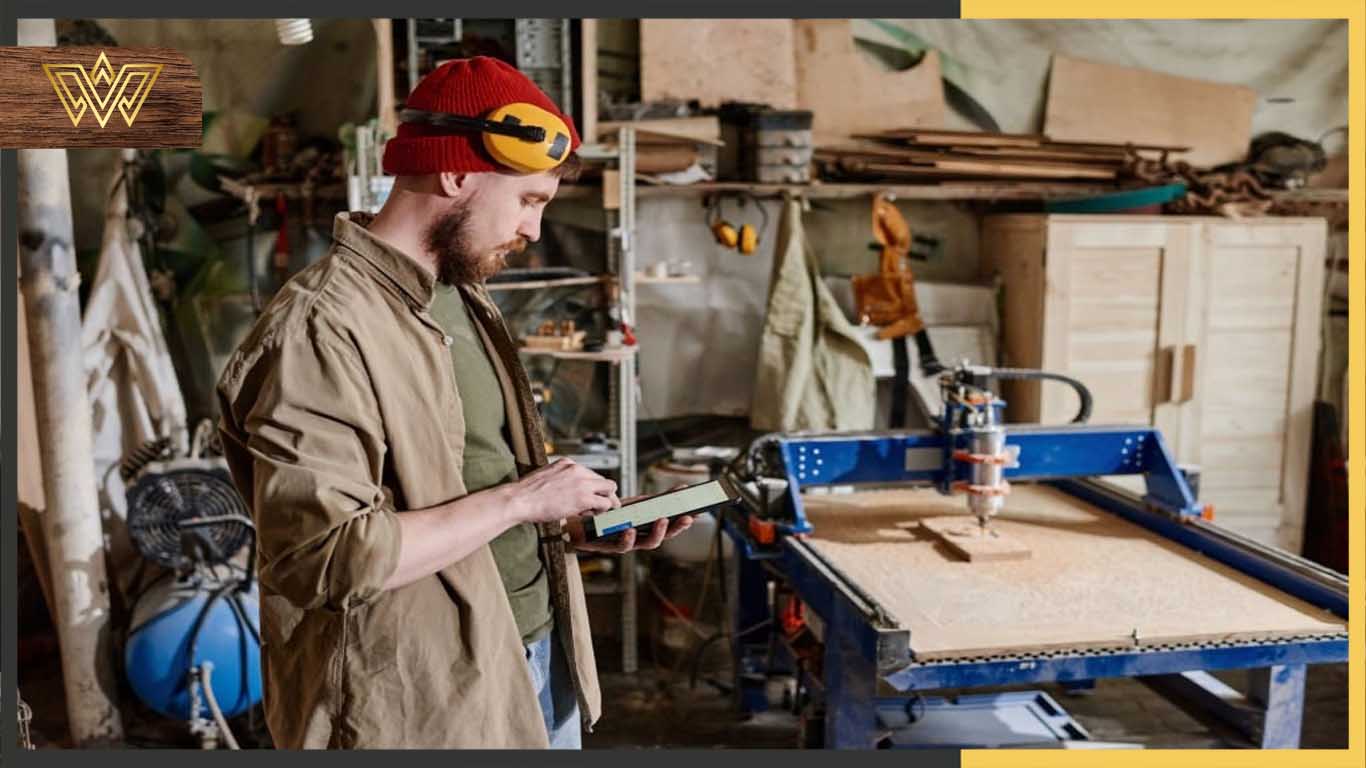

CNC Wood Machine New Technology In Woodcarving Industry

Despite the centuries-old history of wood carving, CNC machine woods are a new technology in this industry.

Here are some of the best producers of CNC machines in woodworking and other industrial sectors.

In the next, we will explain why nested-base manufacturing is crucial for companies to increase their output.

Some of the best CNC machine wood carving manufacturers

Accu-Router

Accu_router is one of the best companies at producing the highest-quality CNC routing machines. Their latest flagship router for high-production machining is Kratos.

Here are some of its main features:

- Table sizes range from 2 by 4 inches to 6 by 12 inches. The table size can be customized, though.

- Twin table and inline shuttle designs

- The open base design lets dust fall through the floor.

- Have a post-processor for interfacing with the most popular software like Mastercam, Plataine, SigmaNEST, etc.

- Equipped with Fanuc electronics for operator convenience, datacom, and optimal cycle time.

- High-speed ball screw assemblies and linear rails

- A 32mm center’s optionally programmable electronic drill

- Speeds up to 3,000 in/min (in XY axes), 800 in/min (in Z axes)

- A fixed bridge, moving table design with a solid aluminum jig plate table.

- Equipped with operator control installed on an overhead arm pendant.

- Many options for improving material squaring and workflow.

- Customizable hold-downs include rollers, flip pods, vacuums, rollers, or a combination thereof.

Thermwood

Thermwood is a US-based, multinational manufacturer of CNC machinery. Thermwood is a manufacturer of high-speed and flexible 3-axis and 5-axis woodworking CNC machines and other CNC routers. Thermwood is the main producer of high-speed 3-axis and 5-axis all kinds of CNC routers.

The CNC routers of Thermwood are unbelievable, reliable, and serviceable. They can work 24 hours a day, 7 days a week, and 365 days a year with minimum maintenance. Most importantly, you can work with its products for years without experiencing technical problems.

“Cut Center,” one of Thermwood’s best CNC machine tools, is a great alternative (without the need for programming) to traditional wood CNC routers. Cut Center can produce large items such as closets, furniture, doors, drawers, and cabinets.

Stiles, a reputable manufacturer in CNC routing & machining

This manufacturer produces CNC wood carving machines and CNC routers. Stile also produces CNC machines for aerospace, plastic, and so on.

The main features of their products are:

- Complex shapes

- Precise tolerance

- High processing speed and accuracy on two or more axes

- creating highly detailed components from costly raw materials

- Eliminate human error while performing tedious and dangerous projects.

- Motion control and programmability

CMS Deutschland GmbH

One of the leading international manufacturers of CNC 5-axis machining centers is CMS. The machines of this company are one of the best CNC machine wood on the current market.

The company also produces CNC routers that are great for processing composite materials (GRP, CFRP), model building materials, aluminum, and wood-based materials.

CMS machines are high-quality, motor-driven, and robust. They are made based on sophisticated, modular mechanical engineering and offer process-reliable solutions for all machining requirements.

Nested-based manufacturing

“How can a manufacturing company like us manage materials and labor well?” you may be wondering.

The answer is simple: with the help of nesting software and a well-built CNC machine wood design. This approach enables us to use many required components in a compact arrangement.

How might nested-based manufacturing (NBM) assist businesses in boosting productivity?

First, consider the alternative of a woodworker using the manual point-to-point method to work on a part. Then consider a project with 20 different pieces, each requiring layout, drilling, and sawing. If you have to do each piece separately, you’ll need 60 “tool changes’ to get all 20 pieces.

With a CNC machine and a nesting program, you’ll need only three tool changes to drill, profile, and cut out all 20 pieces. Furthermore, CNC wood router machines enable us to complete projects at a faster rate.

A significant point:

Because no direct human intervention is necessary, a CNC router operator can be preparing other sheets for the machine or perform other tasks while the router is machining.

Nesting and its relationship to return on investment (ROI)

CNC machine woods enable us to make more cuts, increasing material costs while decreasing waste. Overall, manufacturers expect a 30% reduction in material usage, meaning a positive ROI.

It all means less use of wood and other materials and environmentally conscious operation.

Who may profit from nested-based manufacturing (NBM)?

All companies that produce ready-to-assemble furniture, kitchen cabinets & doors, and so on will significantly benefit from CNC machine wood cutting.

For example, a wood CNC machine coupled with nested-based capabilities would be ideal for those companies that produce a large flow of cabinets each month. Because of automation, they can expand workloads without increasing production time. Therefore, they will not need to go through a costly recruitment process.

Is nesting more effective for low- or high-volume production?

The short answer is yes. It will be ideal for high-volume orders, especially if the parts have complex shapes. At the same time, it can help low-volume and bespoke work companies because there is no need for setup requirements.

Some potential concerns about nesting

Here are the two main concerns of a CNC wood designing machine:

- speed of machining

- reduced output (lower yield)

These two issues are brought up because a router tool’s kerf is wider than a saw kerf. However, these two factors shouldn’t be a problem.

As for concerns about lower yield, the ability to nest parts like a jigsaw puzzle is more than the router’s larger kerf.

The nesting software makes the process of placing components on a material sheet easy. Therefore, it can maximize yield while allowing the router to cut in any direction.

The essential advantages of NBM and CNC machine wood projects

The key benefits of NBM and CNC machine wood are accuracy and consistency.

Each set of CNC router parts will always be within tight tolerances. While this consistency makes the nesting process predictable, it also decreases the need for replacement parts and repairs. The finishes on all edges are substantially superior, thanks to the better tool speeds and feed. Moreover, there is less setup time and machine downtime.

In the end, NBM and the CNC router enhance many business operations. They shorten manufacturing cycles through improved efficiency while lowering inventory costs, boosting output, and enabling a company to respond to changes in work and workflow more quickly.

Takeaway

At Woodyart, we are a local manufacturer offering a variety of materials with varied texture options. So, no matter what your dream kitchen cabinet is, we can make your imagination a reality.

You can always rely on us to provide stunning products at the most affordable price.

So, why hesitate? Contact us now and enjoy your dream cabinetry.